| Product Type: | Ceramic Heater |

| Product Color | White,Black |

| Power (W): | 900/1500W |

| Gift Box Size (L*W*H) | 16*17*20cm |

| Qty/CTN | 1PCS/CTN |

| Weight | 980G |

| MOQ | 2 PCS |

| Certificates: | CE,CB,EMC,RoHS,ErP |

| Wind | 3 Grade, speed 1.57m/s~2.71m/s |

| Safety Protection Function | Tip-Over & Over-Heat Protection |

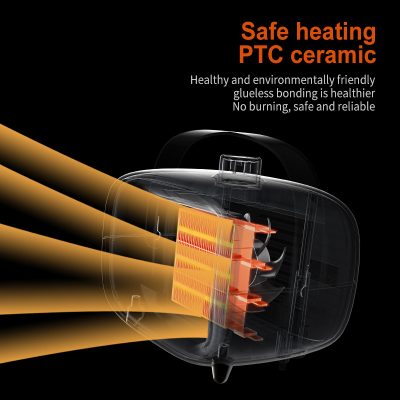

The ceramic heater is a high-efficiency heater with uniform thermal distribution, a metal alloy with excellent thermal conductivity, which ensures a uniform temperature of the hot surface and eliminates hot and cold spots in the equipment. There are two types of ceramic heaters, namely PTC ceramic heating element and MCH ceramic heating element. The materials used in these two products are completely different, but the finished products are similar to ceramics, so they are collectively referred to as “ceramic heating elements”. Ceramic heaters have the advantages of long life, good thermal insulation performance, strong mechanical properties, corrosion resistance, and magnetic field resistance. The preparation method is to cast alloy wire in a semiconductor with quartz glass as raw material. It has the characteristics of high temperature resistance (up to 1200 degrees), anti-corrosion, beautiful and wear-resistant. Widely used in aquarium fish tank heating, high temperature heating furnace, semiconductor engineering, glass, ceramics and wire engineering. The ceramic heater uses different materials to print the heating element inside the ceramic body and sinter it in one piece.

The ceramic heater uses different materials to print the heating element inside the ceramic body and sinter it in one piece. This structure can be completely airtight, and very delicate heating circuits can be designed. In addition, the design of the heating circuit is also very flexible, the shape/power can be adjusted arbitrarily, and multiple circuits can be designed to realize the functions of switching and temperature sensing. The ceramic heater uses different materials to print the heating element inside the ceramic body and sinter it in one piece. This structure can be completely airtight, and very delicate heating circuits can be designed. In addition, the design of the heating circuit is also very flexible, the shape/power can be adjusted arbitrarily, and multiple circuits can be designed to realize the functions of switching and temperature sensing.